Hydraulic fluid is essential for the transmission of hydraulic power or energy, in a range of industries from construction and agriculture to logistics and manufacturing.

Any heavy-duty machinery that applies force by pulling, pushing, squeezing, lifting or moving does so by transferring power or energy via hydraulic fluid, from a pump, through a hose, to a ram and cylinder, for example.

What’s hydraulic oil made of?

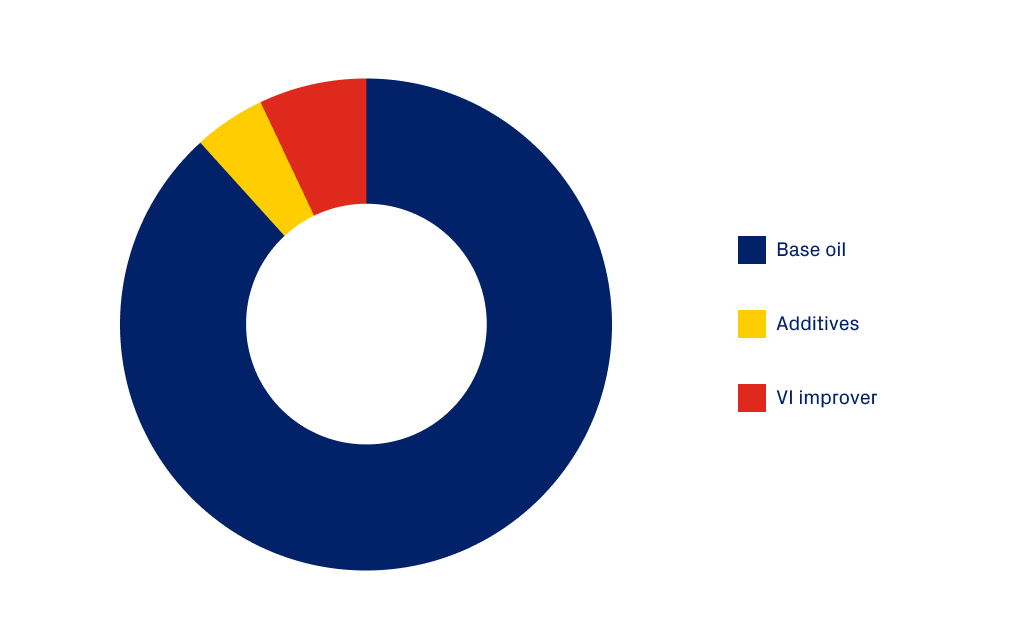

As can be seen in the diagram, hydraulic oil contains three properties, the main one being base oil plus an additive package and optional Viscosity Index (VI) improvers.

Hydraulic Fluid Properties

What are the different types of base hydraulic oil?

There are different quality levels of base oil; virgin oil, recycled or manufactured oil, environmentally friendly oils (known as bio oils) and specialist oils, for example, fire resistant hydraulic fluids.

The benefits of virgin oil

Compared with recycled or remanufactured oil, virgin oil lasts longer and has about a third of the oxidation rate, i.e lasting for 6500 hours as opposed to 2000 hours. Oxidation will occur when oxygen mixes with the oil, as the chemical reaction creates a ‘varnish’ in the hydraulic system, and excessive heat will accelerate this varnishing effect. Recycled or remanufactured oil will become sticky and varnish systems more quickly, which leads to sluggish operation and increased wear. Over time, this will block lines, filters and valves.

What’s in an additive package?

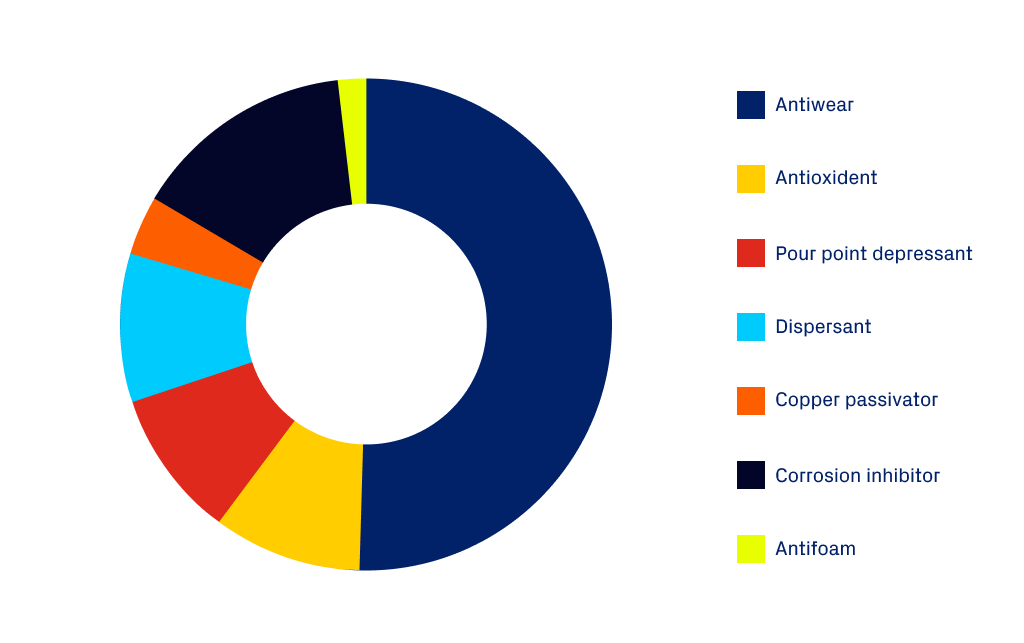

The additive package, which is added to the base oil in hydraulic fluid has various properties, including;

- Antiwear– prevents metal to metal contact between parts

- Antioxidant – designed to prevent the occurrence of oxidisation (sludge/varnish)

- Pour point depressant – stops wax crystals forming at low temperatures

- Dispersant – prevents fine particles from settling and building up

- Copper passivator – binds to copper surfaces and creates an impermeable boundary

- Corrosion inhibitor – decreases the corrosion rate of a material, typically metals

- Antifoam – minimises the formation of bubbles and ‘foaming’, typically silicone base

Additive package properties

Why is the viscosity of the fluid important?

Viscosity is a measurement of a fluid’s resistance to flow; the higher the viscosity, the greater the resistance.

It’s measured in centistokes, which is the number you see at the end of any part-code e.g. Hyd-oil 46. The higher the number, the greater the resistance to flow and the thicker the oil will be.

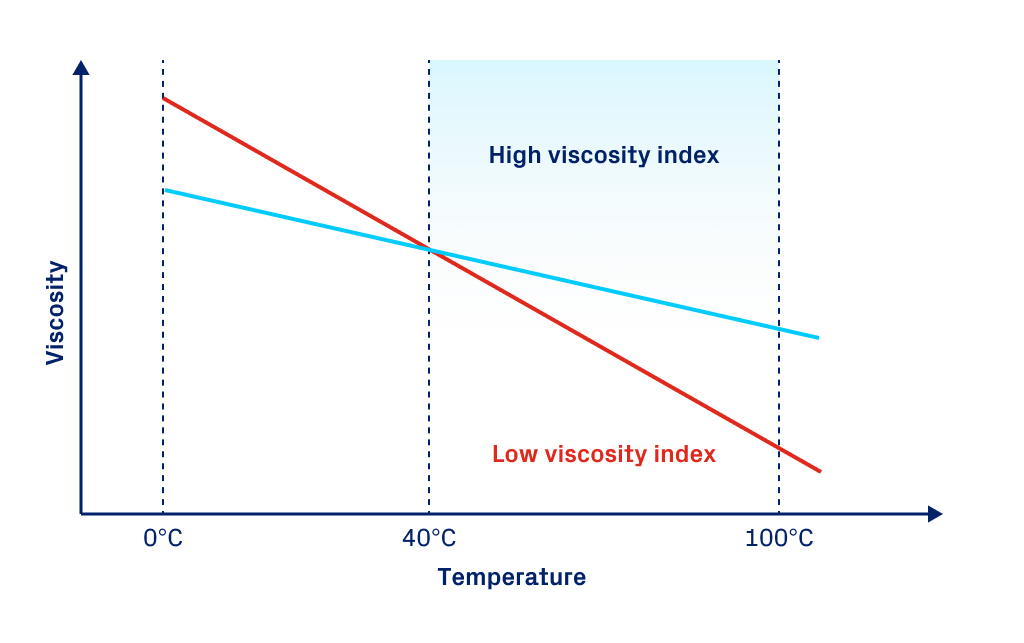

The Viscosity index is how a fluid’s original viscosity is affected when exposed to various temperatures. Any oil becomes more fluid at higher temperatures, and the Viscosity Index marks the degree to which this effect applies: oil with low Viscosity Index will exhibit more pronounced extremes, such as being very fluid at high temperatures and very thick at low temperatures; oil with high Viscosity Index will tend to maintain relatively similar properties at low or high temperatures.

Note that some hydraulic oils will have viscosity index improvers, aimed at obtaining more consistent performance over a wide range of operating temperatures. This is often indicated in the part code e.g.Hyd-oil-46 VHV1, where the VHV1 stands for a very high viscosity index.

As you can see in the diagram, the blue line represents an oil with a VI improver.

Note – Most hydraulic systems run with a typical ISO viscosity grade in the range of 22 – 68.

High viscosity

If the viscosity is too high and the fluid is too thick, it can cause a number of problems:

- Higher resistance to flow in the system

- Increased energy consumption caused by increased friction, leading to increased input torque required at the pump end

- High temperature created by power loss to friction

- Increased pressure drops due to increased resistance to flow

- Slow or sluggish operation

- Inefficient separation of air from the oil in the reservoir

- Pump cavitation

Low viscosity

Likewise, if the viscosity is too low and the oil is too fluid, it can mean:

- Increased internal leakage

- Excess wear or seizure, (particularly of pumps) if heavy loads have caused a breakdown in the lubrication between moving parts

- Decrease in pump efficiency caused by increased leakage and possible cylinder blow-by. This could lead to increased cycle times or slower machine operation.

- Internal leakage causing an increase in operating temperatures.

How do you know the right viscosity?

There are many types of hydraulic oil, as required by different types of machinery, ranging from 5 centistokes ISO (Kinematic Viscosity @ 40°C) to 220.

The vast majority of applications require either 32 or 46, with other specialist oils being necessary for a small percentage of applications. 10W oil, for example, which is classed as engine oil, can be used by some machines for power transfer purposes just like standard hydraulic oil, as specified by the manufacturer.

What does ISO VG stand for?

Short for International Standards Organization Viscosity Grade, the ISO VG classification was introduced in 1975 as and has been universally adopted as the standard unit for determining oil viscosity ever since. This enables the data to be interpreted by manufacturers and suppliers around the world, regardless of their country of origin.

What’s ISO VG and why has it been developed?

The purpose of the ISO VG system is to determine an oil’s viscosity or its thickness which is measured as resistance to flow at any given temperature.

Each oil is graded, after which it’s assigned an ISO VG number between 2 and 1500 that categorises its viscosity, i.e.how dense or thin it is. Oils with a higher viscosity (i.e.oils that are more dense) have a slower flow rate, and sit higher on the ISO VG numerical scale.

Why is an oil’s ISO VG number important?

The ISO VG number of an oil will help you to work out if an oil is the right viscosity for its intended use, so it plays a vital role in the performance of your hydraulics powered systems.

Using an oil that’s not the correct ISO VG number can cause premature wear to your machinery, poor heat dispersion or raised temperatures, all of which may result in serious hydraulics failure that could take your operations offline.

How can you select the right hydraulic oil?

Hydraulic oil is available in a range of viscosities (determined by the ISO VG number or cSt) as well as different chemical makeups – both synthetic and water-based.

Which hydraulic oil to use for your application depends on the operating temperature and pressure of your hydraulics system, together with the type of pump that powers it.

Synthetic hydraulic oils, for example, are better geared towards hydraulics machinery where pressures and temperatures can peak and swing, while water-based oils are more suitable in instances where fire poses a heightened risk.

That’s why you need to weigh up a number of variables, such as the viscosity grade, the hydraulic oil type and the additive package in terms of antiwear (AW) or rust and oxidation inhibitors (RO).

Choosing the right grade of hydraulic oil

When it comes to selecting the correct viscosity oil for your hydraulics machinery, always make sure you follow the manufacturer’s instructions and choose a viscosity that falls within the specified range for your system’s hydraulic pump.

By sticking to the recommended guidelines, you will keep your machines in good working order and minimise the risk of any hydraulics breakdowns, which could take your business temporarily offline.

With that in mind, it’s important to schedule regular servicing and maintenance from a qualified hydraulics technician who can safely assess your systems, including the hydraulics oils.

Making the move to biodegradable oils

Biodegradable hydraulic oil products are growing in popularity for a number of reasons.

- Increased environmental awareness – Although not completely harmless, biodegradable fluids are less toxic than petroleum-based oils so cause less damage in the event of a leak or spill. Governments around the world have brought in many regulations aimed at protecting the environment.with significant fines for those who violate the rules, and high clean up costs.

- Cultural change – Many hydraulic system owners or Original Equipment Manufacturers (OEMs) have been waiting to see the industry’s response to bio oils. As more guidance becomes available from industry standards groups, the user base will grow, which will ultimately lead to biodegradable natural esters becoming the primary choice of hydraulic fluids.

Four types of environmentally friendly hydraulic fluids are commonly used:

- Hydraulic environmental triglyceride – HETG

- Hydraulic environmental ester synthetic – HEES

- Hydraulic environmental poly glycol – HEPG

- Hydraulic environmental polyalphaolefin and related – HEPR

They all have pros and cons so it’s worth exploring the options carefully.

Advantages

Some bio oils are highly biodegradable and non-toxic. Many also have high viscosity, excellent lubricity and good oxidation stability. What’s more, they can offer good corrosion protection and a long service life. They significantly reduce the environmental impact of oil spillages and, therefore, they are widely used in machinery that operates near, on or in water.

Disadvantages

Some environmentally friendly fluids age quickly and are miscible with water which can damage their biodegradability. In addition, some can cause extreme thickening and gumming, affecting machine performance. Be aware that with some bio oils you may require a special system design.

Transitioning to bio oil

If you are considering making the change, vegetable based hydraulic fluids are used in the same way as a traditional, mineral, hydraulic oil. Remember, however, never to mix mineral and biodegradable products and bear in mind the industry standard stipulates a maximum pollution level of 2%. It’s worth consulting your fluid supplier, equipment manufacturer and seal supplier before converting your system to an environmentally friendly fluid to check they are compatible.

Whatever hydraulic fluid you’re using, whether it’s biodegradable or not, make sure it’s in good condition and monitored frequently. Always speak to a qualified technician to make sure you’ve got the right hydraulic oil for your system.

Oil sampling and fluid analysis

The quality and purity of the oil in your system can degrade over time, depending on the temperatures and working conditions its subject to – as well as any small contamination of the system cause by hose failures. This can compromise the long-term health of your machinery, potentially causing costly issues. It is possible, however, to assess the health of the hydraulic oil in your system. Specialised equipment can be used to sample and analyse the fluids on-site, and assess whether a total or partial replacement is needed.

Follow this link for more information: Pirtek Oil Sampling and Fluid Analysis

For any help with oil selection or to arrange a check-up of your hydraulics system, contact your local Pirtek centre or trade counter.

Select a country